Lokta paper: Reliable income source

The paper making business has become a reliable income source of many rural entrepreneurs of Nepal. So, it is very important to make this process sustainable, cost-effective and competitive

Lokta paper is a traditional handmade Nepali product prepared from lokta fibre. The lokta fibre is possibly one of the longest and strongest natural fibres, thus paper made from it is very strong and has a unique texture. The paper is one of those rare products of Nepal in which all the elements of supply chain (raw material, labour, expertise, etc.) are based on local resources.

A typical paper making factory has an investment level of about NPR 30,000 to NPR 200,000 with average sales turnover of each enterprise NPR 9.5 million in year 2005, as reported by GIZ (2007). Of the total products, only 10% are sold locally and the rest find good markets in Europe, Japan, and USA.

According to the Federation of Handicraft Associations of Nepal (FHAN) handmade paper products are the 5th largest export products in the handicraft category. The industry currently employs about 4000 families in rural areas in paper making and another 2500 people in Kathmandu in paper product making, 80% of them being poor women from disadvantaged ethnic groups, as reported by GIZ (2007). So, its promotion can add value in alleviating rural poverty in hills of Nepal.

Modern handmade paper industry in Nepal started in 1980s with the establishment of Bhaktapur Craft Printers but the art of making paper from lokta was started since the 12th Century AD in the hills of rural Nepal. However, by 1950s’ cheap machine- made papers from India overtook the market and pushed this traditional paper into near extinction.

It was only in the 1980s that modern handmade paper industry in Nepal started with the establishment of Bhaktapur Craft Printers. The lokta entrepreneurs however managed to revive this industry by publicizing it as environment friendly and natural product.

Moreover, the government in March 2009 decided to use it for citizenship certificates, identity cards, letter pads, and government stationery giving it further space to flourish. Besides this, lokta paper has many interesting and important uses. It is extensively used in government offices and courts because it is durable, resistant to insects, and non-perishable.

It is a must in preparing astrological charts or chinas. Over the years, its use has diversified to commercial purposes. It is widely used as incense, visiting cards, festival decorations, greeting cards, note books, calendars, lamp shades, envelops, as it is easy to dye and is very soft. Virtually, anything can be made from paper, from toys to fashion garments; limited by the imagination.

The paper is prepared from the bark of Daphne bholua and D. papyracea. According to Department of Forest, Government of Nepal, it is available in over two million hectares of forests in 52 districts, all of them in the hills. However, paper production is currently done only in 32 districts. Until the beginning of 2003, about 313 handmade paper enterprises were registered with the Department of Cottage and Small Industries (DCSI).

Paper making is a manual process produced in batches, each consisting 20 Kgs of raw material for processing and produces 1,400 pieces of 5gms papers i.e. 7 Koris. Traditionally, firewood is used to boil lokta barks. The process of paper making starts with collection of bark extracted from lokta shrub at 30 cm above ground to let it regenerate.

Lokta bark is then peeled and transported to the factory, and the rest is left behind as mulch. In a factory, the bark is sun-dried for about 24 hours to remove moisture and stored in a dry place.

Then about 20 kgs of raw material (for one batch paper production) is immersed in water (especially during the night to save time) to soften and cleaned to remove black spots and impurities. The cleaned lokta is cooked in a drum containing water and caustic soda. The cooked lokta is washed with clean water to remove caustic soda and then beaten with a wooden mallet to make it into pulp.

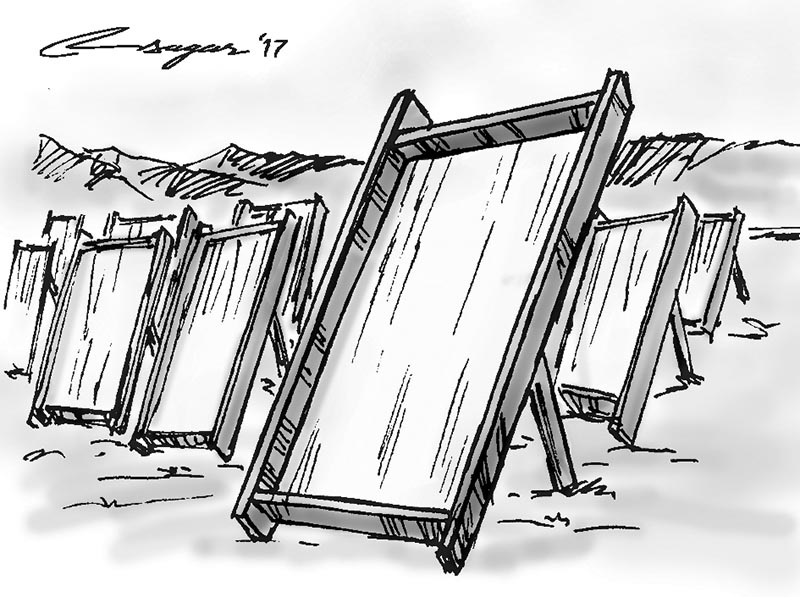

The softened pulp is then molded in wooden frames by spreading the thin pulp to make flat sheets of paper. The thickness of paper desired depends upon amount of pulp poured (500mg for 5gm paper). The frames are dried in sun, after 20-30 minutes (depending upon the weather), and the paper is ready to be taken out of frame.

Generally, the papers produced are 20 x 30 inches in size due to the limited technology i.e. standard frames of 20 x 30 inches size. In the market paper of 40 gm is most popular followed by 20 and 5gm; and thicker the paper, the more is the price.

The processing method is labour intensive, inefficient, and pollutes the environment. So, at present some technological interventions are done like calendaring (smoothening), electric cooking, electric grinding, dip dyeing, and electric boiling and grinding as an intervention of Renewable Energy for Rural Livelihood (RERL) Programme.

Presently, the paper making business has become a reliable income source of many rural entrepreneurs of Nepal. So, it is very important to make this process sustainable, cost-effective, and competitive. In this regard, commercial lokta farming has also started in a few districts of Eastern Nepal. And, the intervention of efficient and environment friendly technology, “electric boiler,” itself is another milestone. Though the upfront cost of boiler is high for rural entrepreneurs, the boiler easily paybacks within a couple of years.

Subash Chandra Kunwar, Aashish Pradhan and Reshu Bashyal contributed to the article